Product application field

● High-grade metallic pigments (high-grade automotive metal paint, etc.)

● Solar electronic paste

● Conductive coating

● Military (gunpowder, various ammunition fillers)

● Aerospace (solid rocket propellant, etc.)

● Smelting alloys (aluminum heat, steel deoxidizer, etc.)

● Anti-corrosion materials

● Refractory materials (magnesia carbon bricks for steel making, etc.)

● Fireworks

● Chemical industry (catalysts, high-precision alloys, precision powder casting parts, etc.)

● Medicine, pesticide industry (pesticide additives)

● Ceramic industry

Product shipping instructions

Transportation and storage requirements

The packaging of aluminum powder is not allowed to be thrown, bumped or inverted during loading and unloading and transportation.

Aluminum powder needs to be transported by boxcar or by means of rainproof measures.

Aluminum powder should be stored in a dry warehouse, no less than 1 meter away from the heating and windows.

Product packaging instructions

Packing specification

|

Serial number

|

Packing category

|

Specifications

|

|

1

|

Inner plastic woven bag

|

30Kg����、40Kg、50Kg

|

|

2

|

Iron drum packaging

|

15Kg、20 Kg��、40 Kg

|

|

3

|

Export iron drum packaging

|

180 Kg�、200 K

|

|

4

|

Tray packaging

|

|

|

5

|

Other packaging

|

|

QC

First, the selection of high quality and stable raw materials

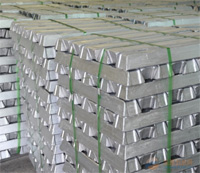

The company's products use the AL99.85 and AL99.9 grade aluminum ingots of the People's Republic of China standard "Aluminum ingot for remelting" GB/T1196-2002 as raw materials for production. The raw materials and indicators of the chemical ingredients are as follows:

|

raw material

|

Aluminum content is not less than

%

|

Impurity content is not greater than0.25%

|

|

|

99.7

|

Fe

|

Si

|

Cu

|

Ga

|

Mg

|

Zn

|

雜質(zhì)總和不大于0.25%

|

二���、Second, the international advanced particle size testing equipment

product description

|

品牌號

|

產(chǎn)品規(guī)格粒徑(μm)

|

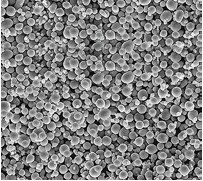

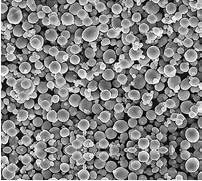

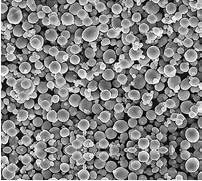

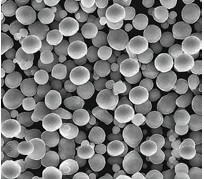

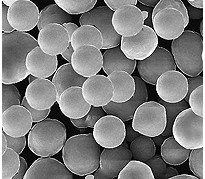

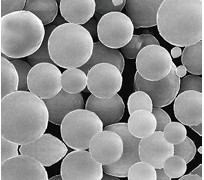

電鏡照片

|

技術(shù)參數(shù)

|

|

活性鋁不小于(%)

|

化學(xué)成份雜質(zhì)不大于(%)

|

|

鐵

|

硅

|

銅

|

水份

|

|

JM5#

|

1-3

|

|

98.3

|

0.2

|

0.15

|

0.015

|

0.1

|

|

JM4#

|

3-4

|

|

98.3

|

0.2

|

0.15

|

0.015

|

0.1

|

|

4-5

|

98.3

|

0.2

|

0.15

|

0.015

|

0.1

|

|

5-6

|

98.3

|

0.2

|

0.15

|

0.015

|

0.1

|

|

6-7

|

98.3

|

0.2

|

0.15

|

0.015

|

0.1

|

|

7-8

|

98.3

|

0.2

|

0.15

|

0.015

|

0.1

|

|

JM3#

|

8-10

|

|

98.5

|

0.2

|

0.15

|

0.015

|

0.1

|

|

9-11

|

98.5

|

0.2

|

0.15

|

0.015

|

0.1

|

|

11-13

|

98.5

|

0.2

|

0.15

|

0.015

|

0.1

|

|

13-15

|

98.5

|

0.2

|

0.15

|

0.015

|

0.1

|

|

15-17

|

98.5

|

0.2

|

0.15

|

0.015

|

0.1

|

|

JM2#

|

17-19

|

|

98.5

|

0.2

|

0.15

|

0.015

|

0.1

|

|

19-21

|

99

|

0.2

|

0.15

|

0.015

|

0.1

|

|

21-24

|

99

|

0.2

|

0.15

|

0.015

|

0.1

|

|

24-26

|

99

|

0.2

|

0.15

|

0.015

|

0.1

|

|

JM1#

|

26-29

|

|

99

|

0.2

|

0.15

|

0.015

|

0.1

|

|

JM0#

|

29-32

|

|

99

|

0.2

|

0.15

|

0.015

|

0.1

|

|

35以上

|

99

|

0.2

|

0.15

|

0.015

|

0.1

|

說明:(1)可根據(jù)客戶要求生產(chǎn)特殊粒徑的產(chǎn)品����;(2)本公司生產(chǎn)的微細(xì)球形鋁粉是采用中國科學(xué)院力學(xué)研究所技術(shù)轉(zhuǎn)讓的氮氣保護法生產(chǎn)工藝����,產(chǎn)品規(guī)格按粒度D50確定�。各項指標(biāo)參照GJB1738-93國家軍用標(biāo)準(zhǔn)和美國軍用標(biāo)準(zhǔn)MIL-A-23950A(AS)微細(xì)球形鋁粉規(guī)范劃分����。公司以國標(biāo)為基礎(chǔ)���,同時根據(jù)市場需求制定了JM001-2013《亞星鋁業(yè)公司微細(xì)球形鋁粉產(chǎn)品規(guī)范》����。